Description

Product description

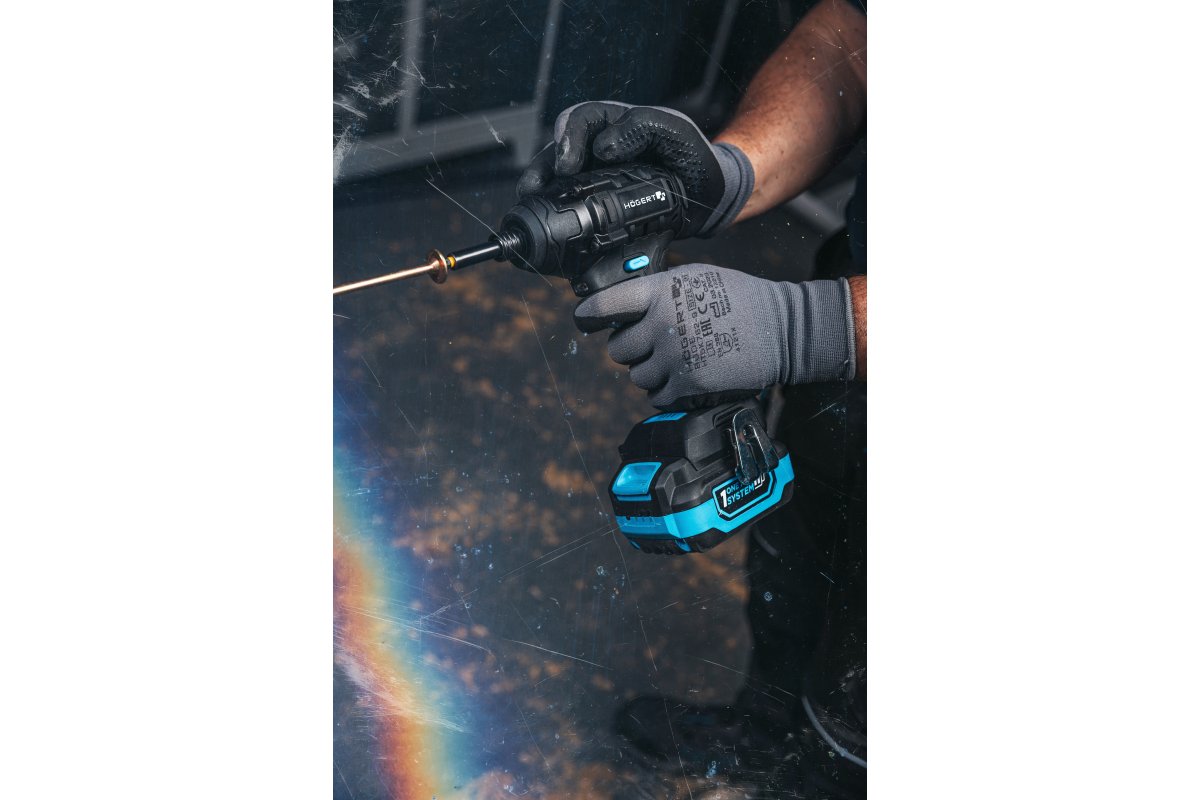

Efficient device that ensuring ease and speed of work for quickly screwing in and out, as well as loosening and tightening, even long screws in wood and sheet metal. Unscrewing and tightening large screws and nuts in metal and wooden structures. Excellent for carpentry workshops and companies creating framework structures from metal and wood. Created for works, which cannot be easily handled with a drill-driver.

Quick-change hexagonal holder, 1/4″ (inch) HEX type, facilitates quick replacement of bits and their secure fixation during work.

High torque of 200 Nm enables working with combined components, requiring high power.

Impact mechanism increases working efficiency at low handle reaction.

Robust anvil in the impact mechanism thanks to excellent materials used to manufacture it.

Three torque settings enable adapting the tool to different tasks, preventing damage to screws, bolts and nuts.

Soft handle enables more reassuring grip of the power tool and dampens vibrations during operation.

Changing the rotation of the power tool in both directions enables efficient screwing in and unscrewing.

Smooth adjustment of rotational speed in the power switch provides greater flexibility and work control.

The built-in, powerful LED perfectly illuminates the workplace even in the darkest areas, eliminating shadows on terminals and connectors.

Brushless motor with innovative construction, thanks to the elimination of brush friction and special magnets offers greater power, longer operation time and lifespan of the device. Advanced electronic circuits continuously regulate the motor operation, optimizing its power according to the performed activity, which translates into efficiency and maximization of the battery operation time.

Durable, metallic housing of the gearbox excellently dissipates heat, making the device more efficient and robust.

Gearbox made of metal enhances the wear resistance and ensures precision of the mechanism.

Thermal safety device protects the tool against overheating during operation.

Rubber bumpers protect the device against mechanical damage.

OneAccuSystem 18 V enables using the selected battery in a wide and diverse range of power tools for the most heavy-duty work.

Characteristic

- Maximum torque – 200 Nm.

- Handle – hexagonal, 1/4” HEX type.

- Rotational speed: 0-900/0-2000/0-2800 Min.

- Torque in gears: 85/ 150 200 Nm.

- Impact Rate: 0–3100 IPM;

- 3 settings of rotational speed / torque;

- Smooth speed adjustment in the power switch.

- Soft, anti-slip handle.

- Right and left rotation direction switch.

- Metal gearbox housing.

- LED light.

- Weight – 1.17 kg.

- Metal gearbox housing.

- Metal gearbox mechanism.

- Brushless motor.

- Device overheat protection.

- 3 years warranty after registering the tool.

- EAN code – 5902801442834.

- 3 years warranty after registering the tool.

- OneAccuSystem.

- Voltage – 18 V.

- The rechargeable battery to be purchased separately.

Downloads

deklaracja_zgodnosci HT2E225-0ID,HT2E255-B14ID, HT2E248-B224IPD_2024_014_CE_NA_Deklaracja zgodności_PL_EN.pdf

Instrukcja HT2E225_248_255__zakretarka_udarowa__instrukcja.pdf

Karta produktowa HT2E225-0ID_PL.pdf

Karta produktowa HT2E225-0ID_EN.pdf

Karta produktowa HT2E225-0ID_DE.pdf

Karta produktowa HT2E225-0ID_RU.pdf

Karta produktowa HT2E225-0ID_CS.pdf

Karta produktowa HT2E225-0ID_HU.pdf

Karta produktowa HT2E225-0ID_FR.pdf

Karta produktowa HT2E225-0ID_ES.pdf

Karta produktowa HT2E225-0ID_UK.pdf

Technical data

| Engine | Brushless |

| Function | Softgrip |

| Handle | 1/4″ HEX |

| Number of gears | 3+1 |

| Producer | GTV Poland S.A., ul. Przejazdowa 21, 05-800 Pruszków, Poland, info@gtv.com.pl +48 22 444 75 00 |

| Rotation speed 1 gear | 0-900 |

| Rotation speed 3 gear | 0-2600 |

| Scope of delivery | basic device, belt clip, bit holder, bit magazine, impact bit 100 mm |

| Speed 2nd gear | 0-2000 |

| Surge Rate [IPM] | 0-3100 |

| weight [kg] | 1,2 |

Högert Technik – professional hand tools of the most demanding users

Durability guarantee / German quality

The careful selection of the highest quality raw materials and the world-class production process guarantee minor wear and long durability of our products.

Quality confirmed

by certificates

Our products meet the strict DIN and VDE standards, which guarantees the highest quality of metals. It has been confirmed by numerous certificates, such as TÜV and VDE. The cutting and grinding discs, on the other hand, are certified by the OSA organization.

Trusted by thousands

of Poles

For years, Högert Technik products have been available in 1300 stores throughout Poland.