Gloves are divided into three categories that define the level of protection against the risk of injury.

Category I: lower protection requirements

The gloves protect against light, predictable in time mechanical injuries with surface effects, e.g. skin abrasion, minor cuts.

Category II: protection against moderate mechanical injury

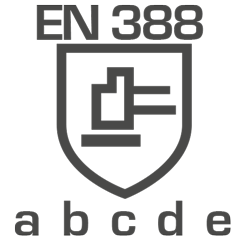

Gloves protect against at least one of the following mechanical hazards: abrasion, cuts, tear and puncture. The level of protection is defined by a pictogram followed by four numbers, each of which is the resistance index to the specific hazard.

Gloves belonging to category II are certified by a notified body and meet the European standard PN-EN 388, which is the standard for gloves protecting against mechanical hazards.

a → abrasion resistance (x, 0-4)

b → blade cut resistance (x, 0-5)

c → tear resistance (x, 0-4)

d → puncture resistance (x, 0-4)

e → cut resistance ISO

The level ‘x’ means that the test cannot be performed on a particular glove.

The indexes take values from 0 to 4 or from 0 to 5 in case of blade cut resistance parameter. Measurements are carried out in laboratory conditions:

| Parameter/(measurement method) | Rating 0 | Rating 1 | Rating 2 | Rating 3 | Rating 4 | Rating 5 |

|---|---|---|---|---|---|---|

| Abrasion resistance/(number of rounds of the grinder) | < 100 | > 100 | > 500 | > 2000 | > 8000 | – |

|

Blade cut resistance/(resistance index of a rotating cutter blade) |

< 1,2 | > 1,2 | > 2,5 | > 5 | > 10,0 | > 20,0 |

|

Tear resistance/(a sample torn in the opposite direction, parameter in newtons) |

< 10 | > 10 | > 25 | > 50 | > 75 | – |

| Puncture resistance/(a sample is punctured with a sharp awl, the parameter in newtons) | < 20 | > 20 | > 60 | > 100 | > 150 | – |

Category III: protection against mechanical injury

The gloves protect against serious injuries and life threatening, such as injuries caused by chemicals, electric voltage or high temperatures.

The OHS inspector indicates the type of gloves that should be used for health threatening work. It can be, for example, nitrile coated, chemical resistant or welding gloves belonging to category III. These products are marked with a pictogram showing the protective functions.

Worth knowing

The choice of gloves should be dictated by the type of hazards that may occur during the work. For light work, fabric and knitted gloves are recommended, they can be spot coated or covered with plastic. So-called combination gloves, combining fabrics and leathers will be perfect.

In order to increase the protective abilities and protect hands against moderate mechanical injuries, leather gloves, gloves coated with rubber or plastic or knitted gloves, e.g. polyester, polyamide or Kevlar are used.

Whilst, special gloves, made of the so-called metal wheels made of stainless steel, protect against heavy mechanical injury.